Integrated dredging solutions

Drying of sludge and sediment

Geosynthetic Container System for Sludge Dewatering

At Nautilus Dragados, we specialize in the dewatering and ecological management of sludge and sediment through the use of geotextile tubes. This innovative system allows for efficient removal of water contained in sludge, facilitating its handling, transportation, and reuse with a low environmental impact.

Why choose sludge dewatering with geotextiles?

Sludge is generated in processes across various economic sectors, and its proper disposal often entails significant technical challenges: sediment can clog navigation channels; industrial mining operations produce large volumes of waste that require environmentally friendly treatment; and a huge amount of sludge is produced daily worldwide as a result of drinking water and wastewater treatment processes. Furthermore, lagoons and ponds, once used as storage solutions, now represent a major problem.

Generally speaking, all types of sludge require a drying process as part of any treatment. Various procedures can be used in this process.

By providing a fast and cost-effective means of sludge dewatering, geotextile tubes are the ideal treatment solution for most applications. The large tubes have high volumetric capacity and optimal filtration performance, while occupying a relatively small area. Geotextile modules can also be used for permanent containment of the sludge cake resulting from dewatering.

The use of geotubes for sludge dewatering has become one of the most effective and sustainable solutions for managing dredging waste in rivers, ports, and coastal areas. Some of its main benefits include:

- Efficient separation of solids and liquids in sludge

- Sludge volume reduction by up to 90%

- Minimum environmental impact in the treatment of sludge and sediments

- Reduction of operating and energy costs

- Ease of transportation and final disposal of dehydrated sludge

- Possibility of recycling treated sludge for reuse in agriculture or construction

How does sludge dewatering with geotextiles work?

The mechanical dewatering process of sludge using geotextile tubes follows these steps:

1. Extraction of contaminated sediments

The first step is sludge extraction. Sediment, for example, can be removed using a suction dredger. Other sludge can be generated continuously as a byproduct.

Benefits of Geotextile

- Extremely high processing speed.

- Direct treatment without the need for temporary storage.

- Online system without intermediate steps.

2. Conditioning

The sludge is conditioned by a chemical flocculant agent, responsible for the agglomeration and agglutination of fine particles suspended in water into groups of larger particles, forming the so-called “flocs”:

Benefits of Geotextile

- Low mechanical loads acting on the flocs (lower breakage potential).

- Reduction (or elimination) of the mechanical equipment required for the process.

3. Drying

The gravity drainage process ensures a constant drainage of water from the sludge mixture inside the geotextile tube. The pore size of the woven geotextile ensures retention of the solids, while allowing water to escape through the geotextile, which acts as a filter element.

Benefits of Geotextile

- Possibility of water recirculation.

- High storage volume capacity.

- Possibility of multi-level arrangement of tubes.

- Easy capacity expansion (adding new modules)

4. Final withdrawal

During the continuous dewatering (consolidation) process, the moisture content of the sludge inside the pipes progressively decreases until it reaches a suitable level that allows its removal, transport and final disposal. The dried sludge can also be reused for another specific purpose.

Benefits of Geotextile

- The encapsulation of the sludge prevents its rehydration.

- Geotextile tubes also allow for permanent confinement of the sludge.

- It requires little space.

Applications of sludge dewatering with geotextiles

The removal of sludge, sediment, and various wet wastes from mines, industrial plants, construction sites, and water treatment systems is generally laborious and expensive.

For these reasons, drying these materials prior to final disposal tends to be the most economical solution.

Geotextile tubes offer a fast, cost-effective, and viable dewatering solution for a variety of materials.

Our sustainable sludge dewatering technology is ideal for:

- Removal of contaminated sediments in rivers and ports

- Restoration and recovery of beaches and marine ecosystems

- Waste management and the environment in infrastructure projects

- Treatment of wastewater sludge and industrial effluents

- Recycling of dredged sediments for construction applications

- Sustainable management of contaminated sludge in dredging operations

Sediments

Sediments sometimes show some degree of contamination by substances such as TBTs, PCBs, and/or heavy metals such as mercury and lead.

Mining waste

Mining processes continually generate a large volume of tailings, which, depending on their composition, can pose an environmental risk.

Industrial Sludge

Industrial processes produce organic and mineral sludge that is easier to store, transport, or dispose of in the form of a dried “cake.”

Construction sludge

Sludge from construction sites (excavations, drilling, etc.) with limited space for disposal.

Sewage sludge

Sewage sludge (a byproduct of biological processes in WWTPs). Small plants generally lack mechanical sludge dewatering equipment.

Geotextile Tubes for Sludge Dewatering

Geotextile tubes provide a fast and economical way to dewater sludge and sediment. The large modules provide high operating capacity and optimal dewatering performance, while occupying a relatively small area.

Made from geotextiles, high-tech fabrics manufactured for this specific application, the tubes can be stacked in multiple levels to further improve the system’s storage capacity. Significant cost savings can be achieved in terms of energy, fuel, and maintenance costs associated with sludge transportation and dewatering, as is typical with other systems.

Geotextile tubes can also be used for permanent confinement of dried and consolidated material without any risk of rehydration (e.g. rain), even during periods of prolonged operation.

As a result, a higher amount of dry solid waste is achieved compared to, for example, drying beds. Geotextile tubes not only act as a durable and reliable containment system, but also somewhat minimize the emission of the characteristic unpleasant odor of sludge.

Advantages of Geotextile Tubes

Three decisive factors

Several factors must be considered when choosing the best sludge dewatering and disposal system for a specific application.

Decision criteria include the required dewatering capacity and operating speed; water quality; reuse possibilities (sludge or percolate); available space; and maintenance requirements. In addition to the above, and equally important, the capital investment associated with system implementation must be considered. Generally speaking, system efficiency is the most decisive factor in most projects. It is important that sludge be removed from problem areas as quickly as possible, enabling a rapid reduction in volume and facilitating disposal, while simultaneously contributing to a reduction in overall project costs.

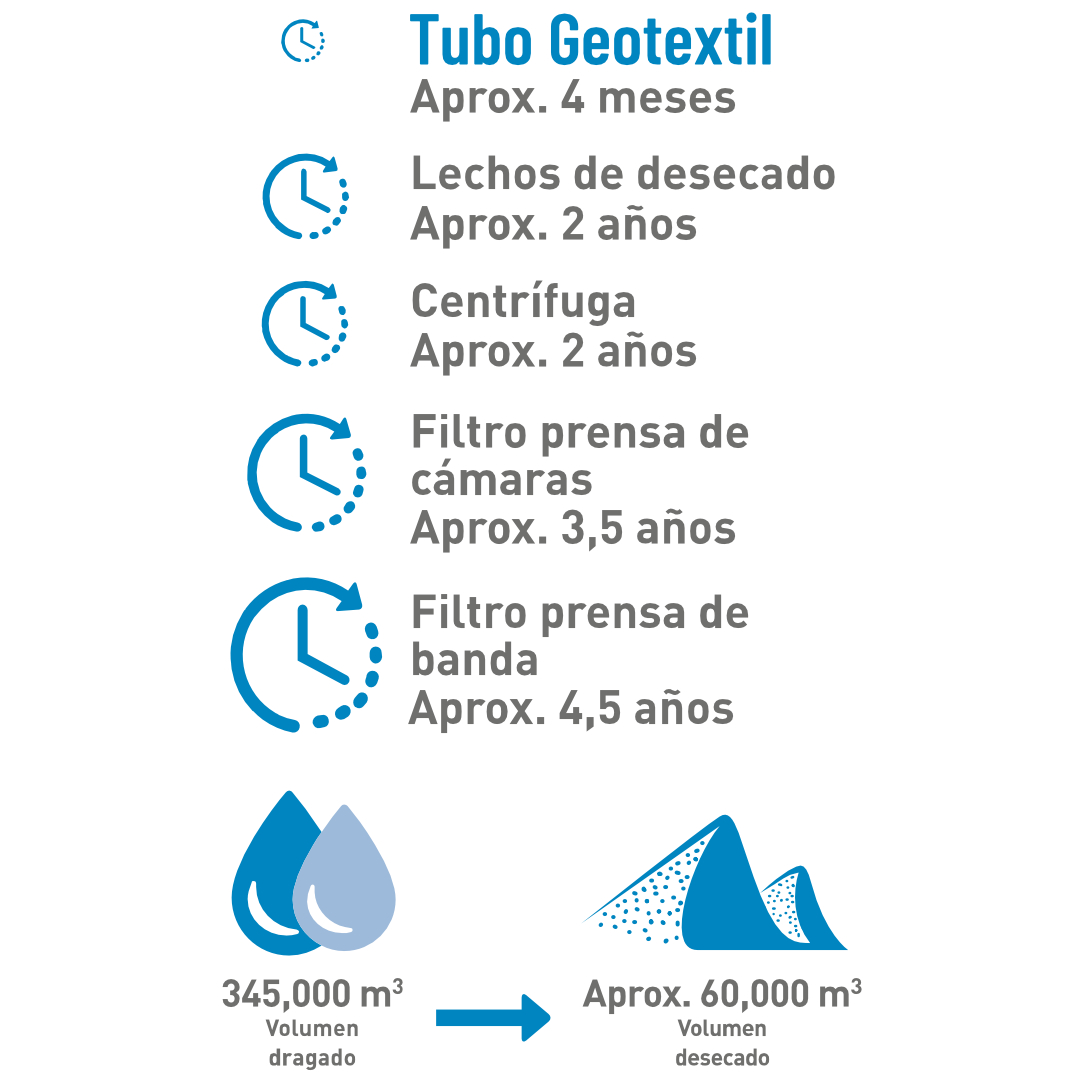

These three crucial factors are illustrated by the following project example for a sludge volume of 100,000 m3 and a dredged volume of 345,000 m3.

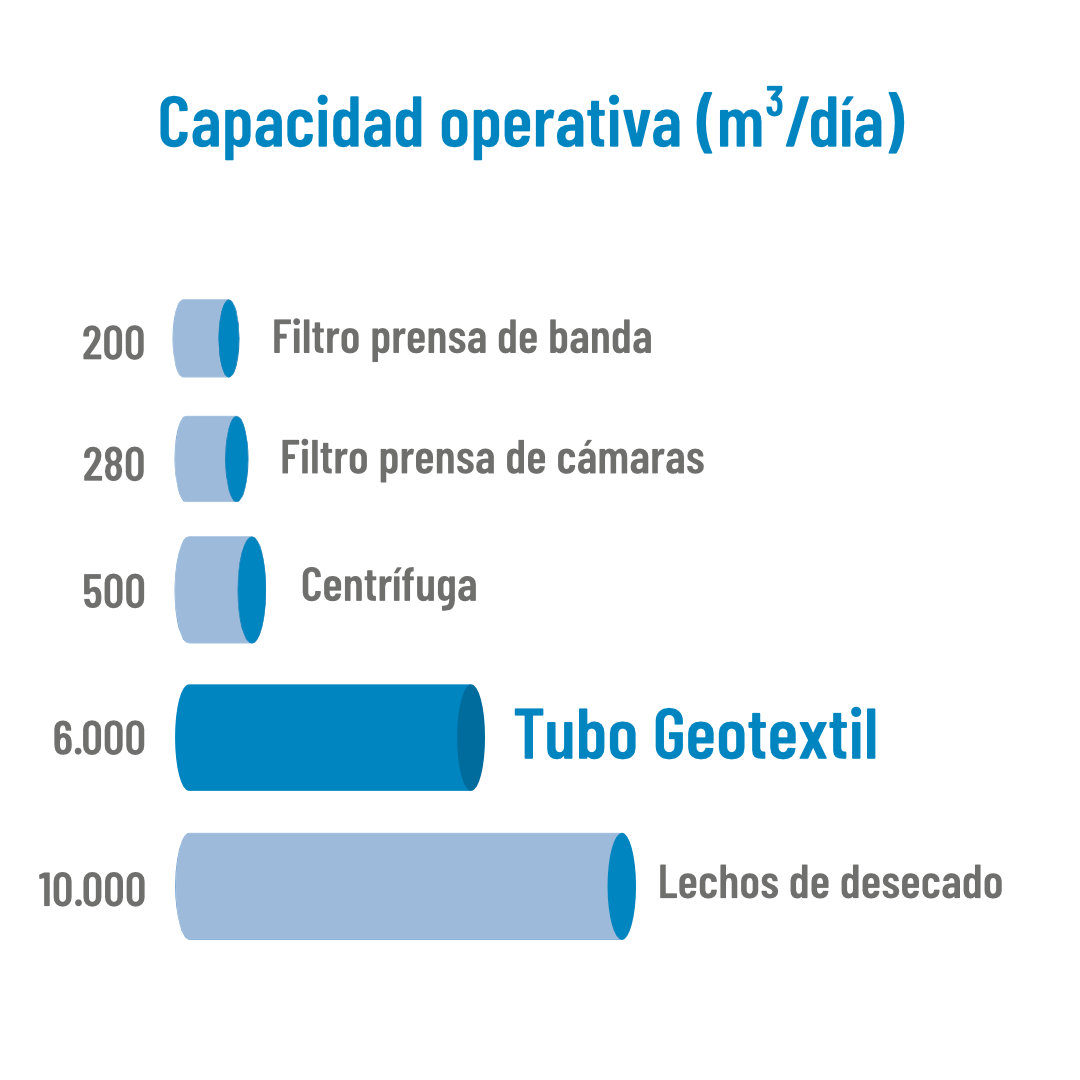

Capacidad operativa

Indicates the volume of sludge that can be processed by the dewatering method in a given period (here, in a ten-hour workday). This stage entails the highest process costs due to the labor and facilities required. Generally speaking, the faster the extraction, the lower the total cost of the dewatering process.

Operating time

In addition to the filling operation, the dewatering process also includes the subsequent volume reduction phase. With the development of the “cake” (dried sludge mass), the material becomes suitable for final disposal.

Geotextile bag modules allow this entire process to be carried out in a short period of time, comparable only to the use of mechanical means. Thus, the use of geotextile bags is equivalent to the operation of 12 centrifuges, 22 chamber filter presses, or 30 belt filter presses.

The diagram presents the comparison based on the use of a single centrifuge or filter press.

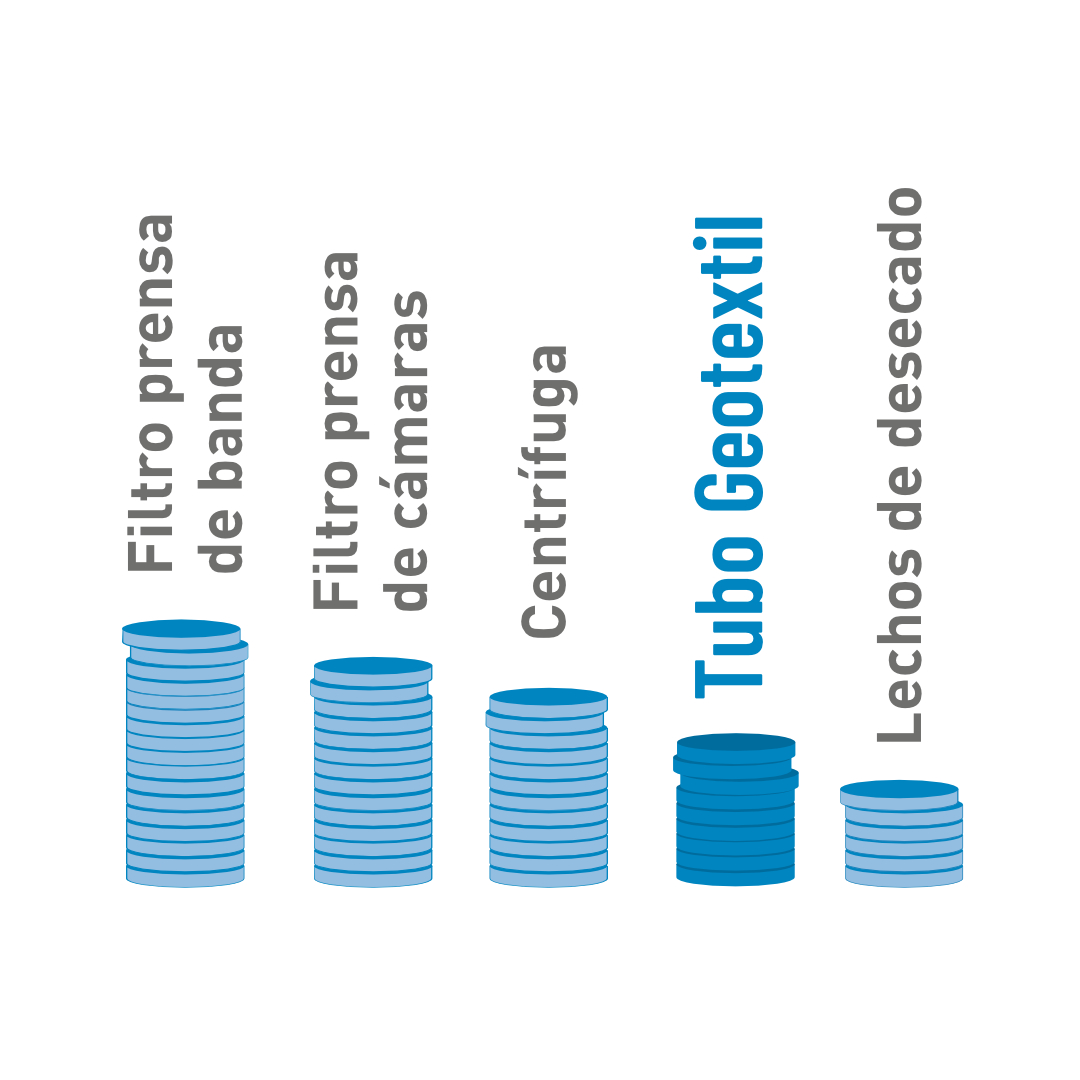

Project cost

In addition to the operational efficiency of a drying system, assessing its economic viability is critical, given that there are substantial cost differences related to labor, facilities, energy requirements, accessories, and consumables needed between different systems.

Commitment to the Environment

At Nautilus Dragados, we are committed to sustainable sludge drying processes, ensuring responsible and environmentally friendly waste management. Our low-environmental-impact sludge dewatering systems comply with current regulations and contribute to the conservation of aquatic ecosystems.

About us

Nautilus Dragados España, headquartered in Málaga, Spain, specializes in the dredging and cleanup of ports, beaches, and other aquatic environments. Originally founded in Norway, the company has accumulated extensive experience in cleanup and restoration projects there. We operate along the entire Mediterranean coast of Spain and part of the Atlantic, covering the entire coast of Spain and Portugal, as well as Morocco. Our commitment to sustainability and the environment is at the core of our mission. We utilize advanced technologies such as polymer/Geobag dewatering to ensure our operations are efficient and environmentally friendly. At Nautilus Dragados, we pride ourselves on providing innovative solutions to address marine environmental challenges.

Contact Us

If you’re looking for an effective solution for sediment and sludge management, contact us and discover the advantages of geotextile dewatering in Spain.

Request information without obligation.